3D Printing & Design

Follow our 3D printing department on facebook:

Need something 3D Printed?

Need Something 3D Printed?

The Basics:

What we do...

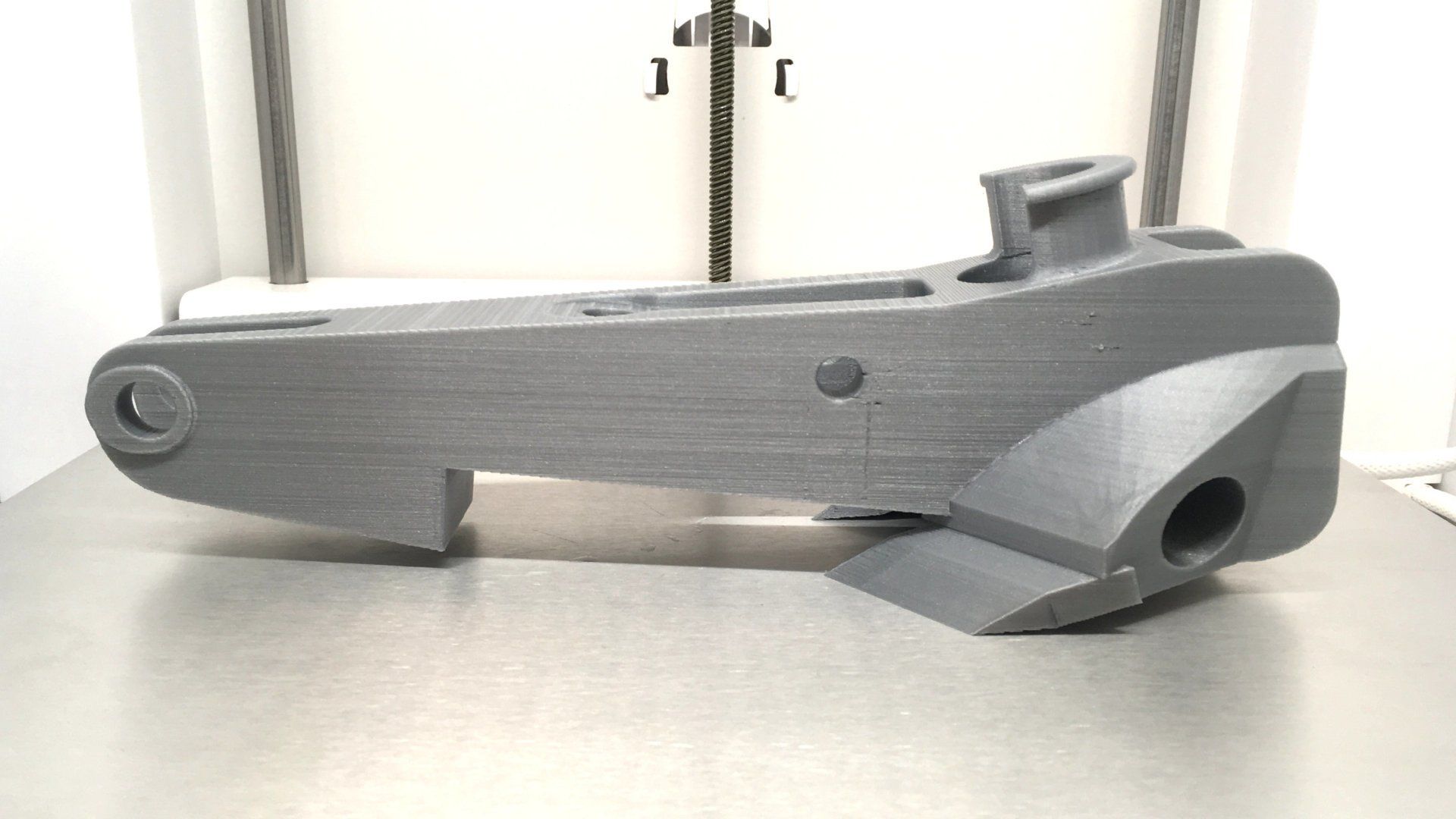

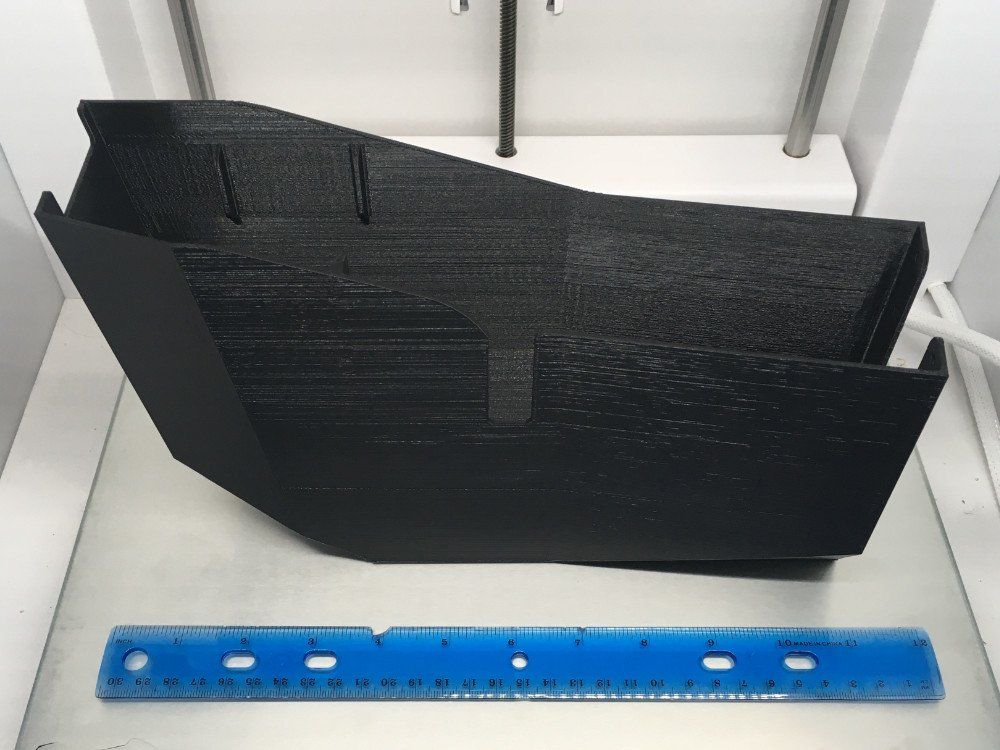

We offer 3D Printing and associated design services, primarily to professionals who are looking to create prototype parts, jigs, tooling and replacements for parts no longer available to purchase. Significant cost and time savings are to be had over traditional short-run or one-off manufacturing methods. We were able to use 3D printing to fast track development of the Technotill Seeding System for our long-time client...

Case in Point:

Why we do it...

"Redesigning Technotill Seeding System components, in the past, has been a lengthy process – sometimes taking 2 to 3 years. In a few months, 3D printing technology allowed us to test and refine the design of the most complicated component of the Technotill packer. Amazingly, the 3D prints were strong enough to allow testing in soil bins and in field conditions. The result, Technotill 2.0, is impressing our customers. Thanks to Jason Knott and Framework Animation for making this possible." - Betty Schoenhofer, Technotill

Process:

How it's done...

All prints start with an idea and then the production of a 3D CAD file describing that idea. There are special considerations when designing for 3d Printing. We have extensive experience with this and can guide the process or take care of it for you. Actual print cost is derived from the type of material chosen, the amount used and the time required to print. Longer print times generally result in higher resolution and a greater aesthetic quality. There are many variables here and we strive to provide the highest quality while meeting budget constraints.

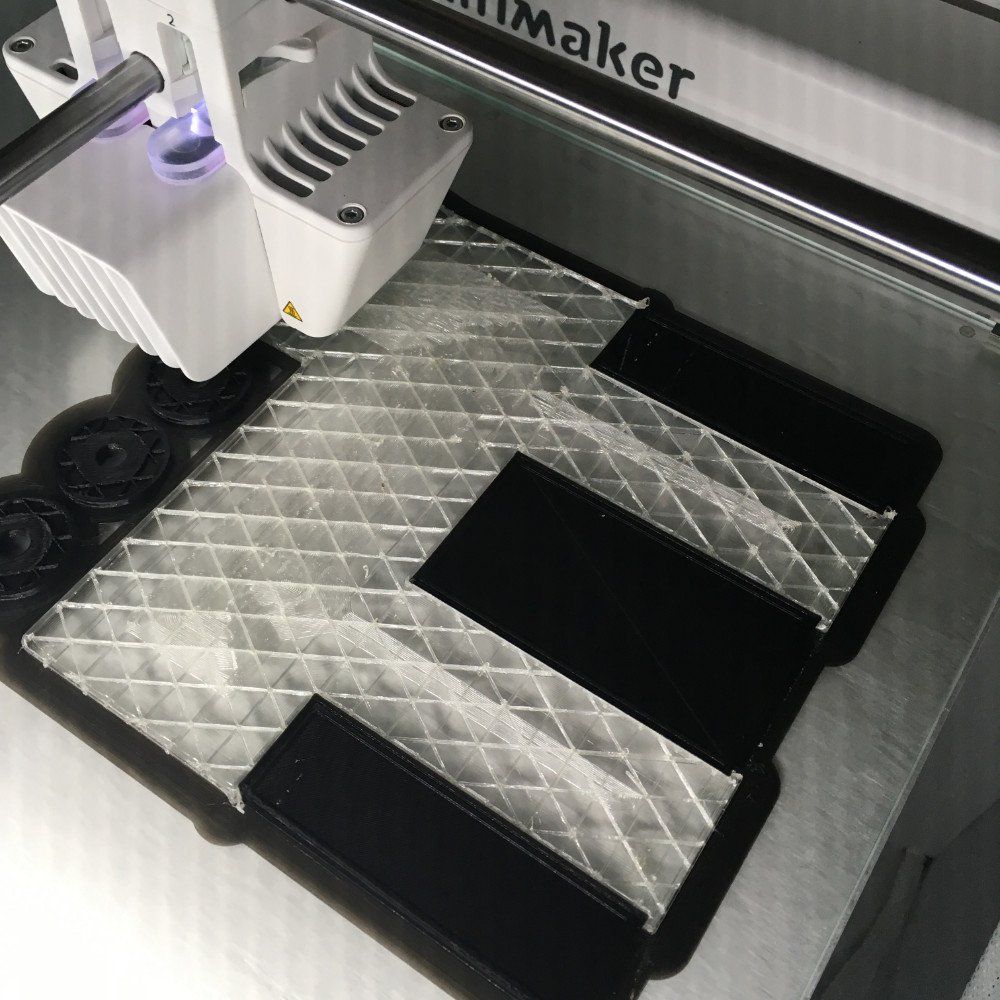

Gear:

We utilize an Ultimaker S5 3D printer, featuring a very large build volume, dual extrusion, a heated bed and a variety of compatible materials. This machine is arguably the best in the business, delivering accurate, industrial-grade parts, time and again, with layer resolution down to 20 microns! We run a full range of print core sizes: .25, .40, and .80, allowing us to balance speed, detail and budget, tailoring prints to your specific needs.

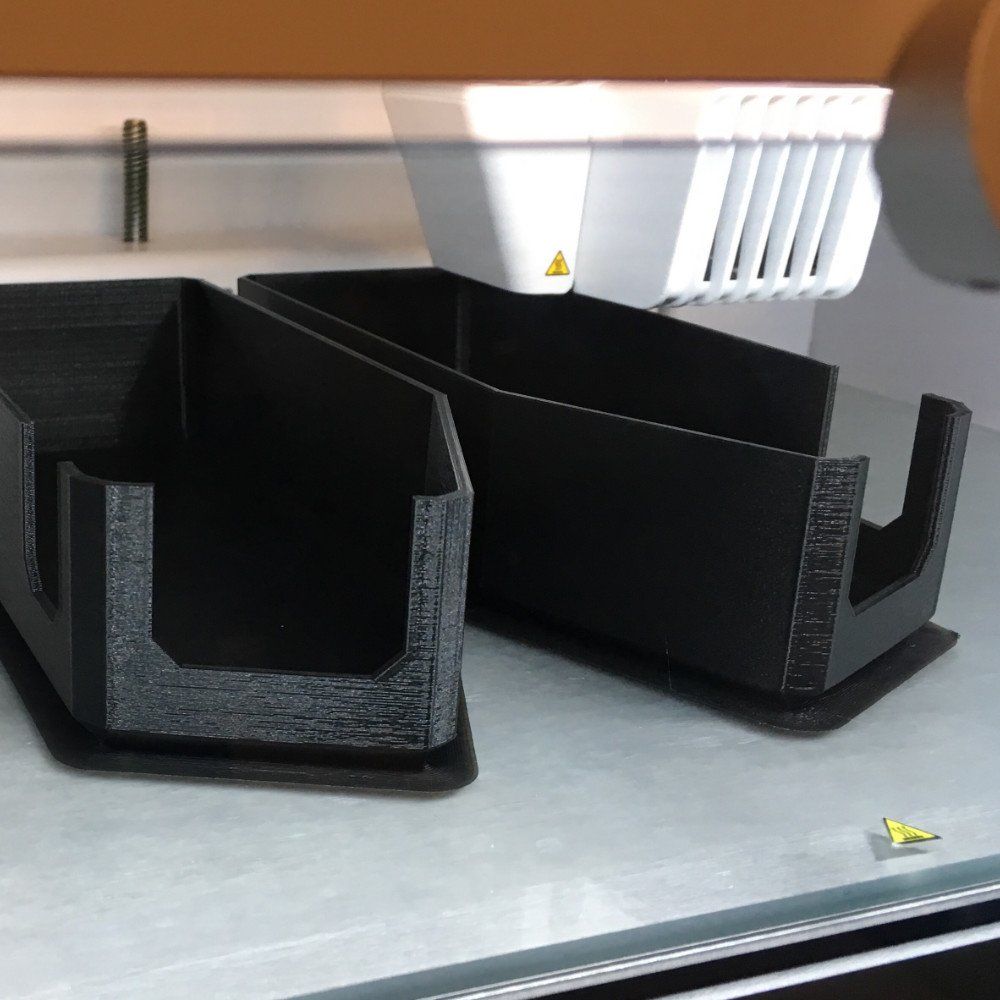

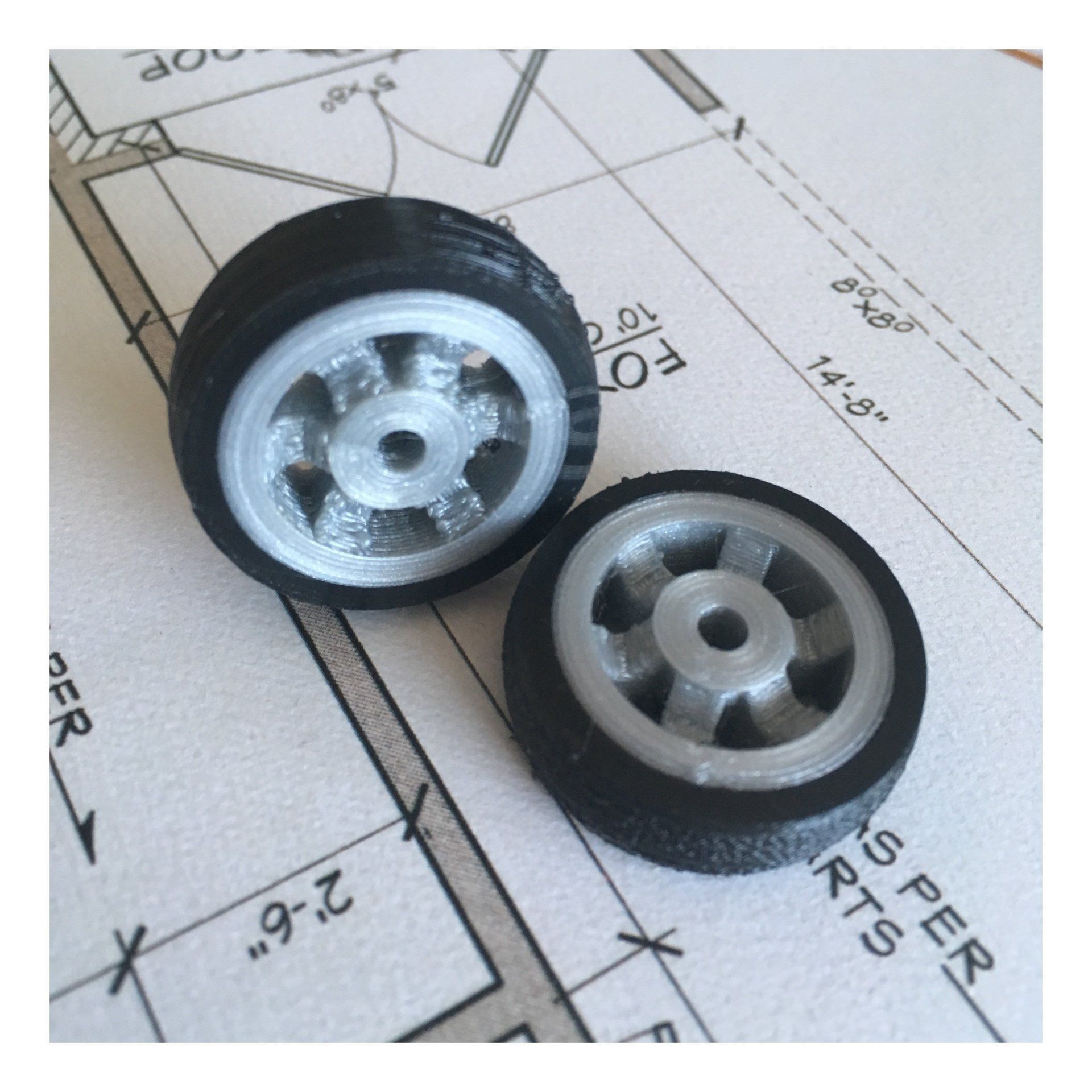

Dual Extrusion:

We are able to utilize two materials in one print. This means that support material can be printed using PVA, which is water soluble and easily removed, leaving a much smoother surface than other support methods. In addition, compatible materials can be paired within a print, such as PLA (rigid) and TPU-95A, (rubber-like). The wheels here were printed in one shot using this combination.

Materials:

PLA (polylactic acid) is highly versatile, easy to print, and available in 11 colors. It prints reliably with high dimensional accuracy and a quality surface finish.

TPLA (Tough PLA) has a toughness similar to ABS and is ideal for printing functional prototypes and tooling at larger sizes.

ABS (acrylonitrile butadiene styrene) can achieve aesthetic detail that rivals injection molded parts.

Nylon is Impact and abrasion resistant with a low friction coefficient and is corrosion resistant to alkalis and organic chemicals.

CPE & CPE+ (co-polyester) excels at chemical resistance.

PC (polycarbonate) retains strength, toughness, and shape while operating in high-temperature environments.

PP (polypropylene) is a durable, chemical resistant material with exceptional fatigue resistance, high levels of toughness, and a low-friction co-efficient.

TPU-95A (thermoplastic polyurethane) has rubber-like flexibility and exceptional wear and tear resistance.